Milling Machine Market Analysis: Trends, Forecast, and Insights (2024-2032)

The global milling machine market size attained a value of USD 84.26 billion in 2023. The milling machine market is further expected to grow in the forecast period of 2024-2032 at a CAGR of 7.2% to reach USD 157.02 billion by 2032. The Asia Pacific is the fastest-growing market for the product. As industries continue to advance and evolve, the significance of milling machines becomes increasingly critical in manufacturing processes, showcasing a steady demand across various sectors. This blog post delves into the intricate dynamics of the milling machine market, exploring its segments, regional insights, and competitive landscape.

1. Market Overview

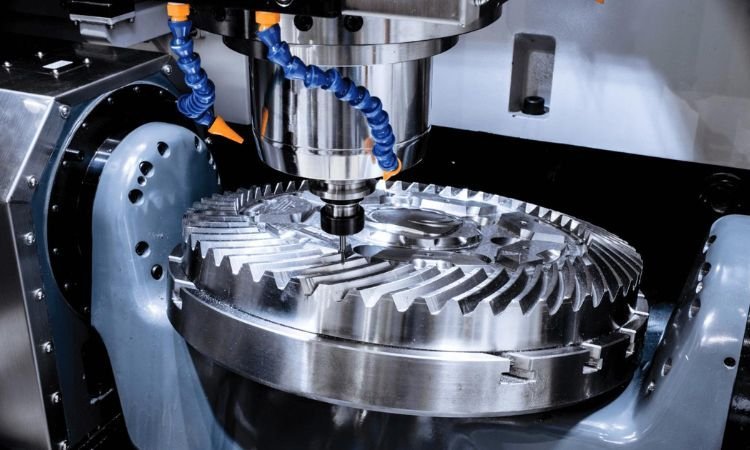

Milling machines are essential tools in various industries, designed for cutting, shaping, and removing material to create precise components. They play a vital role in sectors such as automotive, aerospace, construction, and more. The milling machine market is characterized by a robust growth trajectory, driven by technological advancements and increased industrial production. The anticipated growth from USD 84.26 billion in 2023 to USD 157.02 billion by 2032 reflects a rising demand for efficient, high-precision machinery.

2. Market Segmentation

A. By Mechanism

The milling machine market can be segmented by mechanism into two primary categories: Fraction Rice Milling Machines and Grind Rice Milling Machines.

-

Fraction Rice Milling Machines are specifically designed for the processing of rice, focusing on separating the husk and bran layers from the grain. These machines have become increasingly popular due to the growing demand for rice milling in Asia, where rice is a staple food. The market for fraction rice milling machines is witnessing substantial growth, driven by innovations that enhance efficiency and reduce processing time.

-

Grind Rice Milling Machines serve a similar purpose but emphasize the grinding process, producing fine flour from rice grains. The rising popularity of gluten-free products and alternative flours is propelling the demand for these machines. Manufacturers are investing in technology to improve the milling process, further enhancing market growth.

B. By Direction

Another significant segmentation of the milling machine market is by the direction of operation, which includes Vertical Type Mill Rollers and Horizontal Mill Rollers.

-

Vertical Type Mill Rollers are widely utilized in various applications due to their efficient design and ability to produce high-quality products. Their vertical alignment allows for better control of the milling process, which is crucial in industries where precision is paramount.

-

Horizontal Mill Rollers offer distinct advantages in terms of space efficiency and production speed. These machines are often preferred for large-scale operations where the volume of output is a critical factor. The horizontal design also contributes to easier maintenance and operational flexibility.

C. By End Use

The milling machine market is also categorized by end-use industries, which include Automotive, Aerospace and Defence, Construction Equipment, and Others.

-

In the Automotive sector, milling machines are crucial for manufacturing components such as engine parts and transmission systems. As the automotive industry shifts toward electric vehicles, the demand for precision machining is expected to rise.

-

The Aerospace and Defence industries require high-precision milling machines for manufacturing parts that meet stringent safety standards. Innovations in milling technology are enabling manufacturers to produce lighter, more durable components, driving market growth.

-

Within Construction Equipment, milling machines are used in the production of heavy machinery and tools. As infrastructure projects increase globally, particularly in emerging markets, this sector presents significant opportunities for growth.

-

The Others category encompasses various industries, including electronics and consumer goods, further contributing to the diverse applications of milling machines.

3. Regional Analysis

The global milling machine market is influenced by regional dynamics, with distinct growth patterns across various areas.

-

North America has a well-established manufacturing sector, driving consistent demand for milling machines. The region is characterized by advanced technologies and high standards of precision, which are crucial for industries like aerospace and automotive.

-

Europe also plays a significant role in the milling machine market, with a strong focus on innovation and sustainability. European manufacturers are increasingly adopting automation technologies to enhance productivity and efficiency.

-

Asia-Pacific is recognized as the fastest-growing market for milling machines. Rapid industrialization, coupled with a rising population and increased food processing needs, is propelling demand in this region. Countries like China and India are leading the charge, investing heavily in advanced manufacturing technologies.

-

Latin America and Middle East and Africa are emerging markets with growing industrial bases. While their current share in the global market is smaller, ongoing infrastructure development and increasing manufacturing activities are expected to drive future growth.

4. Competitive Landscape

The milling machine market features a competitive landscape with numerous players vying for market share. Key players include established manufacturers and emerging startups focused on technological innovations. Companies are increasingly investing in research and development to create advanced milling solutions that enhance efficiency and precision.

Strategic initiatives such as mergers, acquisitions, and partnerships are common as companies look to expand their market presence and improve their product offerings. Furthermore, sustainability is becoming a crucial focus, with manufacturers developing energy-efficient machines to meet regulatory standards and consumer demands.

5. Future Outlook

The future of the milling machine market appears promising, with several trends expected to shape its trajectory from 2024 to 2032. Key drivers include:

-

Technological Advancements: Innovations in automation, artificial intelligence, and IoT are transforming the milling process, enhancing efficiency and accuracy.

-

Sustainability Initiatives: As industries strive for eco-friendliness, the demand for energy-efficient and sustainable milling solutions is expected to grow.

-

Increasing Customization: The trend toward personalized products is pushing manufacturers to adopt flexible milling solutions that can cater to diverse customer needs.

However, challenges such as fluctuating raw material prices and the need for skilled operators may pose obstacles to market growth.

What's Your Reaction?